Slide Gate Refractories - Premium Quality from Leading Manufacturers

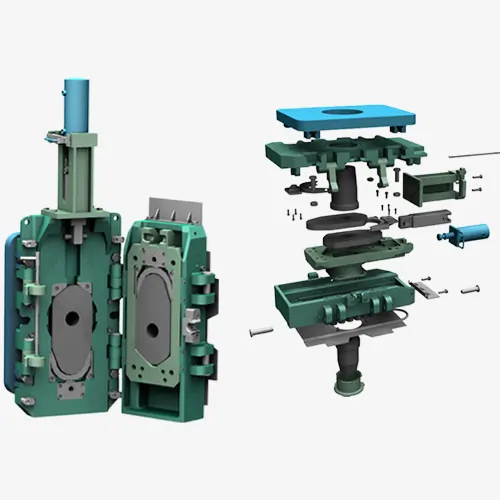

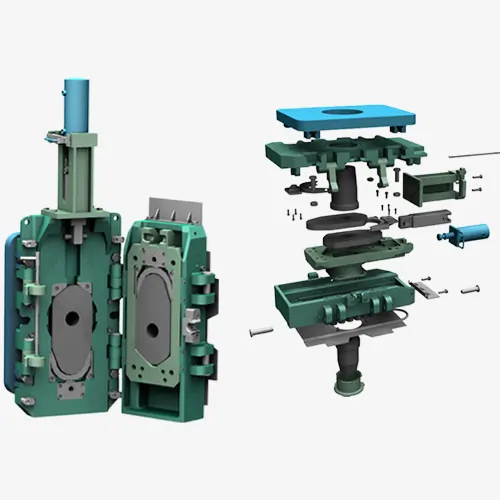

In the steel manufacturing industries and other metallurgical processes, slide gate refractories are considered one of the crucial components. They provide effective control over the flow of molten steel, especially during continuous steel casting operations. They help regulate and stop the stream of molten metal coming from ladles to the tundish or casting molds, ensuring that the output is obtained with precision. Since they are usually operated under high temperatures and mechanical stresses, their design must be capable of withstanding harsh industrial conditions.

Among many reputed slide gate refractory manufacturers in Gujarat, Techno World Corporation holds its position at the top as we craft high-performance slide gate refractories. We ensure that our best-quality slide gate refractory material meets all demanding industrial standards of quality, durability, and performance.

Our manufacturing team of seasoned experts ensures that the raw materials i.e. high-alumina, magnesia, or zirconia are of high purity. They are mixed well and given the required shapes into molds through pressing and casting methods. When they are finely shaped, all refractory pieces undergo a drying process, removing moisture. After that, they are taken into kilns to be fired at high temperatures (as high as 1700°C). The firing process enhances the materials’ thermal stability and mechanical strength. In case of specific requirements precise fitting, further machining, and surface finishing operations take place. Final products coming out of the quality control unit are highly reliable for various purposes.