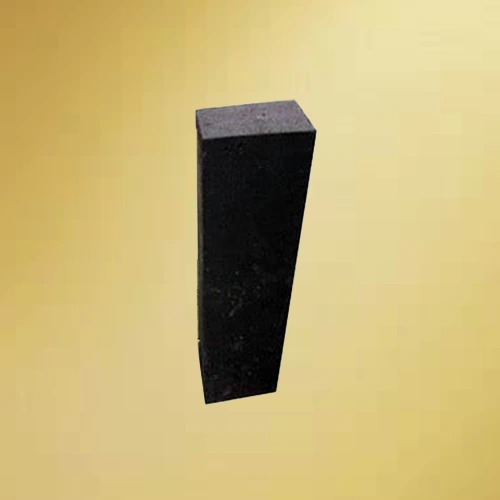

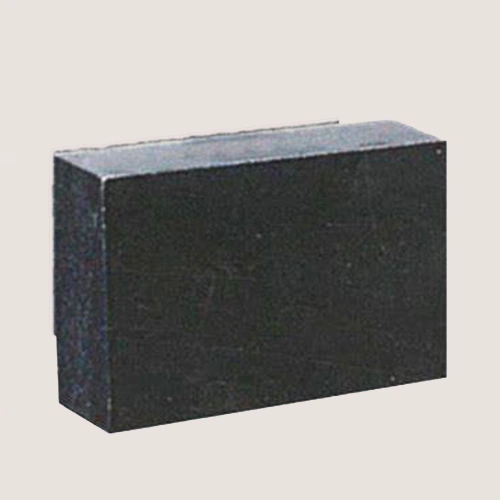

Chrome Magnesite Bricks for High-Temperature Environments

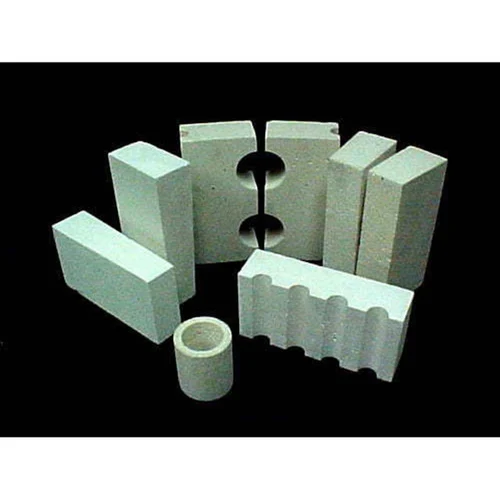

The refractory chrome magnesia bricks, also known as magnesia chrome bricks, are fine-quality fire bricks with the ability to effectively function in severe environments of industrial areas. These refractory bricks are manufactured while maintaining the robustness to be used in various industrial applications.

Each brick is manufactured with the perfect mixture of magnesium (MgO) and chromium oxides (Cr2O3), as they have outstanding properties, i.e. thermal resistance and high anti-erosion capability. Along with these, the refractory chrome magnesia bricks have high mechanical strengths. So, their wear and tear cost is low as compared to other usual bricks. The melting point of these refractory bricks is somewhere around 2000°C or 3,632°F. It makes them reliable bricks to be used for industrial surroundings.

Techno World Corporation is the renowned manufacturer, supplier, and exporter of magnesia refractory chrome bricks in Gujarat and across the globe. We believe that our clients should not compromise on quality when choosing industrial materials and equipment.

Our team of experts ensures that each set of bricks aligns with necessary industrial standards for quality and safety. Engineered for excellence, our refractory bricks are quality-assured to deliver unparalleled operational performance, making them the preferred choice of our clients.