High-Quality Fire Clay High Alumina Bricks - Trusted Manufacturers

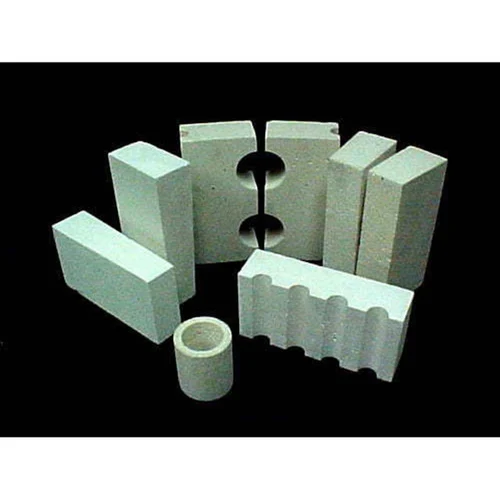

The fusion of high alumina and fire clay makes the fire clay high alumina bricks in demand across industrial sectors for various purposes. These alumina-insulating bricks are manufactured carefully with these two main components to cope with severe conditions due to high temperatures and industrial corrosive environments.

At Techno World Corporation, known as the leading high alumina bricks manufacturers and exporter along with high-grade refractory products, we cater to our potential clients from different industries and meet their requirements. Delivering durable, impurity-free bricks is our company’s goal, and we consistently achieve it.

Usually, during the manufacturing of these fire clay bricks, we ensure that each piece contains 35 to 80% alumina (Al₂O₃). This process enables the bricks to effectively adapt to a wide range of thermal conditions. Our high alumina refractory bricks can withstand temperatures as high as 1800°C or 3272°F. Our dedicated staff make sure that no bricks leave our quality control department which is not meeting the international quality standards.