Bottom Pouring Refractory Set Manufacturers

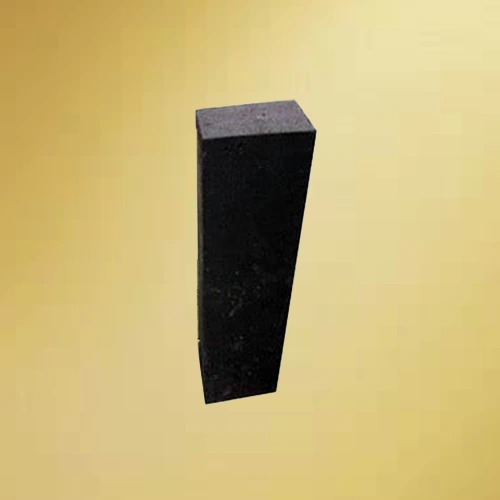

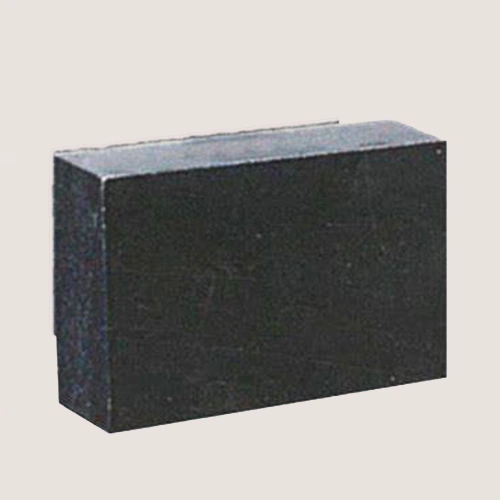

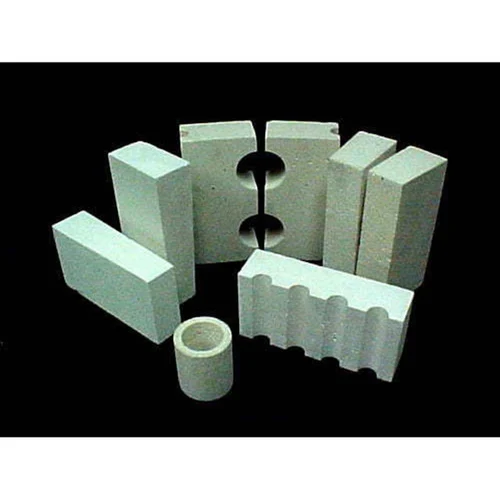

In steel and foundry industries, refractory bottom pouring sets are used to accurately and efficiently pour melted metals from ladles into molds. These elements are required to have high temperature and pressure-bearing properties. Also, these sets are designed to make sure that the flow of the liquid metals is controlled and to restrain any defects that may take place during the casting process.

At Techno World Corporation, we proudly manufacture the highest quality bottom pouring set to contribute to industrial growth. Each set goes through proper quality assurance, leaving no room for damage or less effectiveness to any product piece. The bottom pouring sets we build possess a neutral chemical nature and resist extreme heat and moisture levels without losing their operational efficiency.

We are a renowned supplier and exporter of the high-grade refractory products across nations and beyond. We believe that industries across the globe should benefit from using our bottom pouring sets in their industrial operation and shape a better future.