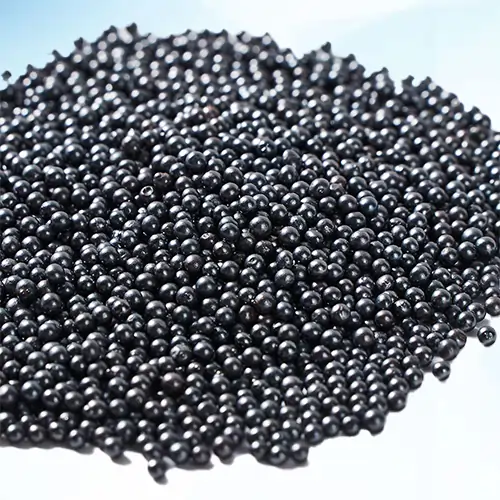

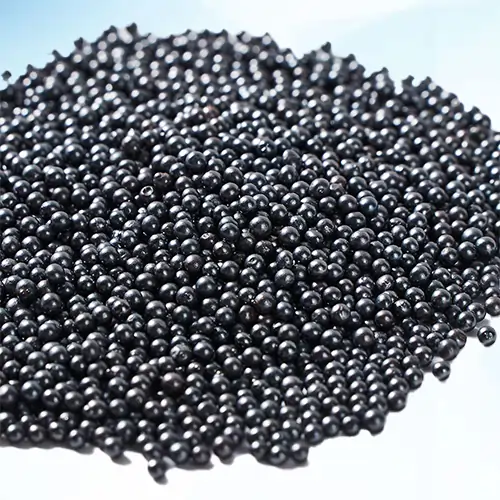

Steel Shots - High-Performance Solutions from Leading Manufacturers

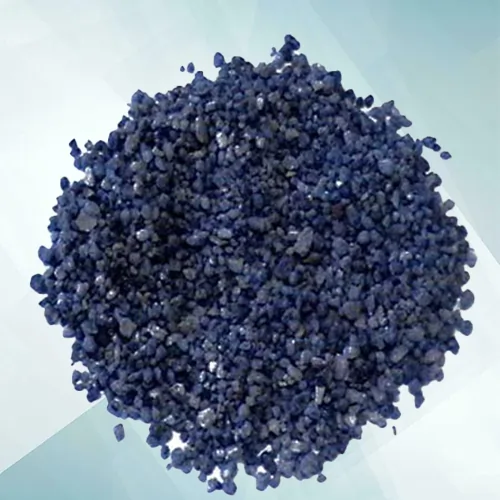

Steel shorts are ball-shaped abrasive grains manufactured from molten steel by following an atomization process (A process of breaking down metals or any other substances into tiny particles or droplets). After the formation of these shots, they go through a heat treatment to make sure that they possess good hardness and are durable enough to withstand severe conditions. Their round shape enables them for beneficial penetration and coverage. This makes them highly preferred for surface preparation, cleaning, and strengthening different types of materials.

As renowned as the leading steel shots manufacturer and exporter from Gujarat, Techno World Corporationcrafts solutions rather than mere products. Our dedicated production unit team carefully designs steel shots that are highly in demand for various industrial applications.

For manufacturing these demanding steel shots, we precisely choose high-grade steel and let them go through the melting process in an electric arc furnace. Then this molten steel is cast into ingots. Later they are cooled down and then go through a series of heat treatments to increase their durability and hardness. Then as we have discussed above, an atomization process takes place, in which the molten steel is blasted through a nozzle and cooled down, turning them into spherical shots. Then these shots undergo a polish and screening process to obtain desirable, uniform quality.