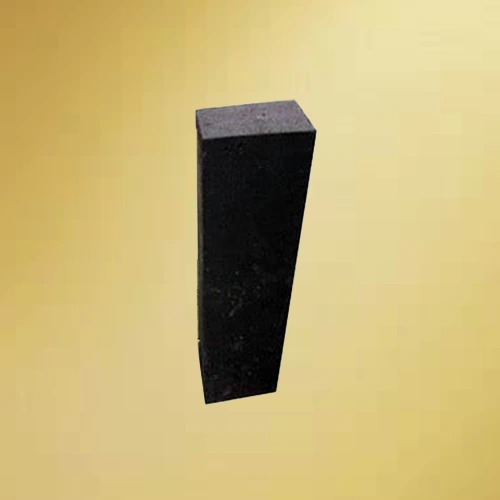

Magnesia Carbon Bricks - Premium Quality from Trusted Manufacturers

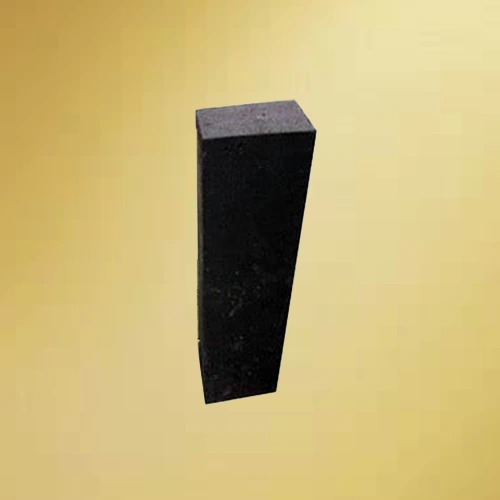

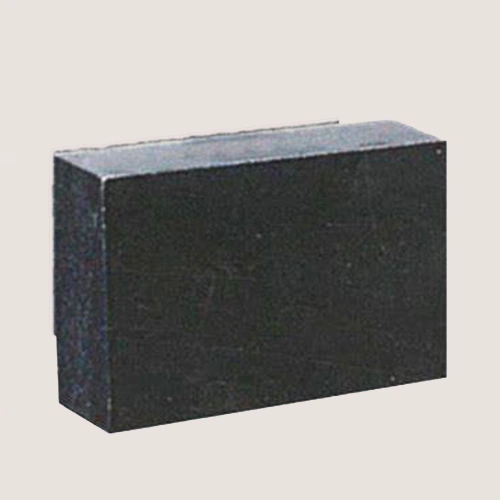

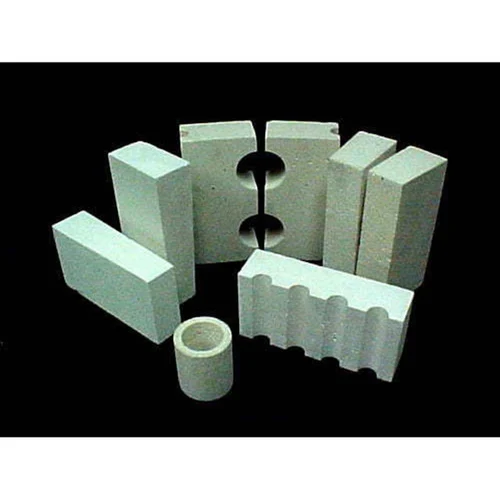

Unlike usual bricks, magnesia carbon bricks are built differently with a unique mixture of Magnesia and (MgO) carbon. These bricks are capable of withstanding higher temperatures, chemical reactions, and thermal shock. The combination of these materials makes these bricks best suited for various industrial purposes where durability and reliability are of utmost importance.

We, at Techno World Corporation believe in crafting the finest refractory materials like Magnesia bricks. We carefully blend the materials used to make the bricks highly appreciable for extreme surroundings where corrosion and wear and tear level possibilities are high.

Our professional team ensures that the bricks that are manufactured at Techno World Corporation are of high quality, exceeding industry standards. We are also the supplier and exporter of these high-caliber refractory magnesia carbon bricks to various parts of the world, to help industries grow and have a transformative impact on an international level.