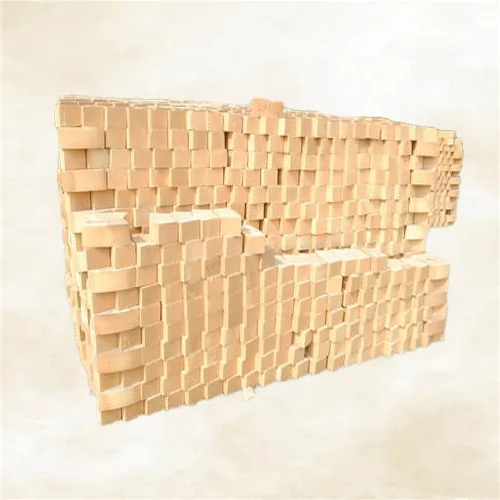

Ceramic Foam Filters - Manufacturers & Exporters

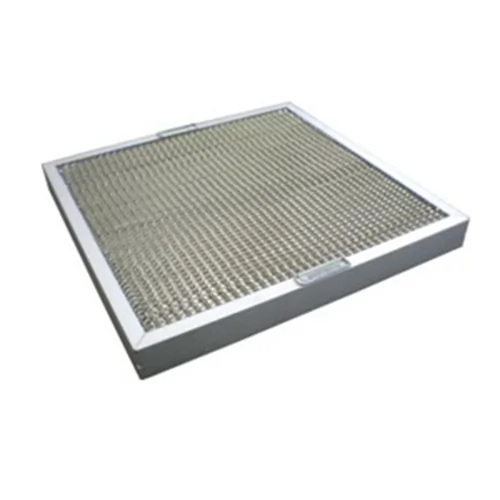

Among various types of filters used in industrial settings, ceramic foam filter is one of the specially designed product. The use of high-grade ceramic content in the manufacturing process gives these filters a robust nature, allowing them to easily withstand high temperature and harsh industrial environments. The open-shell structure of this filter improves filtration properties, removing impurities from the molten metals, and ultimately enhancing the quality of the final products.

At Techno World Corporation, we take pride in involving a highly strict manufacturing process, ensuring that our products meet all the demanding industrial requirements. Along with other equipment and industrial spares, we manufacture high-quality ceramic foam filters that can be suitable for different settings and applications.

The main ingredients in the production of these premium-grade filters are ceramic powder (i.e., silicon carbide, zirconia, alumina, etc.) and polyurethane foam. The slurry is formulated by adequately mixing these materials with alcohol or water-based binders and some additives (i.e. dispersants, plasticizers, and anti-foaming agents). This process is done carefully to make sure that the slurry has the right viscosity, which is crucial for using them to coat the foam structure without pores and clogs.

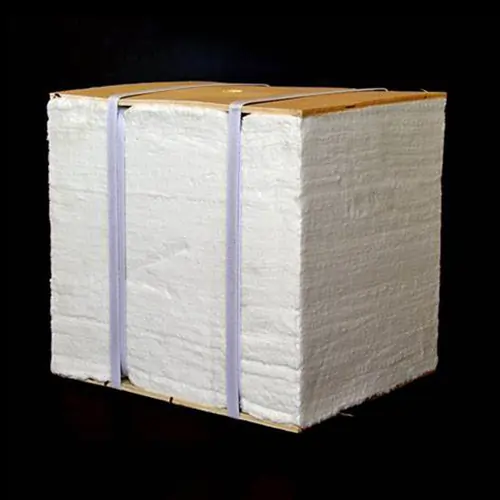

A polyurethane foam is dipped inside the slurry for the uniform coating. Then the foam stays still for drying out and then undergoes a pyrolysis process at 600°C to 800°C, removing the polyurethane from the foam. Then the sintering process takes place to give ceramic the strength it requires, followed by the cooling, trimmering, and quality control process. The final products are then packaged, stored, and delivered to the clients’ designated location. Along with the usual foam filter, we offer its specific variant- silicon carbide ceramic foam filter, which is available as per requirements by our clients.